NEMA Premium Efficiency Motors

Determining the Payback

Reading Electric, a leading supplier of Electro-Mechanical Equipment & Repair Services for over 50 years, provides technical information to the region’s Industrial and Commercial Community. This Bulletin is the third in the Technical Information Series providing information on the recently approved Premium Efficiency Motor Rebate Program.

Reading Electric, a leading supplier of Electro-Mechanical Equipment & Repair Services for over 50 years, provides technical information to the region’s Industrial and Commercial Community. This Bulletin is the third in the Technical Information Series providing information on the recently approved Premium Efficiency Motor Rebate Program.

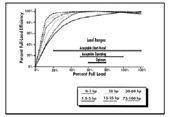

The most common error made is calculating the electrical efficiency payback when replacing a motor with a premium efficiency motor, because only the motor manufacturer’s nameplate stated efficiency is normally used.

To avoid this situation, it is necessary to understand the ‘true operating cost’ of your motor(s) if an informed decision is to be made regarding repairing an existing motor or replacing a motor.

Most users of motors are not overly concerned with the motor, rather the concern is the performance of what the motor is driving, i.e., pumps (gph), blowers (cfm), gear boxes, etc. It is easy to get ‘bogged down’ with the many parameters that affect motor efficiency. This includes the environment, utility service, and of course, the condition of equipment the motor is driving.

A good place to start is to establish a motor performance base line with easily taken measurements that are excellent indicators of the motor system’s performance. The measurements are:

- Motor Amperage at full load operation

- Temperature readings at bearings

- Vibration Reading

All of these measurements are easily taken and analyzed for trending. The Motor Amperage measurement will indicate if the motor is sized properly for the application providing there is not abnormal operation with the equipment being driven.

Taking these measurements every 3 or 6 months will provide confirmation if the motor system is stable and performing in a ‘normal’ condition. Even though these measurements are easily taken, it is strongly recommended that a qualified technician take the measurements and that the analysis is reviewed by another qualified technical person. It is important to note that not performing this analysis and evaluating the Load Profile may create a situation where using a premium efficiency motor does not achieve the expected payback, and in some cases, could actually use more energy.

Taking these measurements every 3 or 6 months will provide confirmation if the motor system is stable and performing in a ‘normal’ condition. Even though these measurements are easily taken, it is strongly recommended that a qualified technician take the measurements and that the analysis is reviewed by another qualified technical person. It is important to note that not performing this analysis and evaluating the Load Profile may create a situation where using a premium efficiency motor does not achieve the expected payback, and in some cases, could actually use more energy.

With this motor performance information, a better decision can be made regarding the payback of replacing the motor with a premium efficiency motor, or deciding to repair the motor to bring it back to original efficiency. As a rule of thumb, a motor’s efficiency degrades approximately ¼ % per operating year. It is critical that the premium efficiency motor be properly sized for the application to ensure maximum energy savings. It is recommended to consult your Motor Supplier to ensure proper motor selection and to do the Premium Efficiency Motor Payback Calculation.

Recent Comments